Our hygienic paints and hygienic varnishes are technical and functional coatings widely certified for sectors where prevention and hygiene are a priority, such as the food industry, healthcare sectors, hospitals, pharmaceutical industry, and cosmetics. It stands out its high physical-chemical resistance, to high humidity and its consequences, to the action of cleaners and disinfectants, especially in technical and industrial environments. Fakolith hygienic varnishes and paints are tested and treated with the innovative antimicrobial technology BioFilmStop (BPR Art.3) highly effective against fungi (mold), bacteria and biofilm and other pathogenic microorganisms such as Coronavirus. This range is suitable for painting, coating, renovating and protecting mainly walls, ceilings, flooring, sandwich panel, clean rooms and food industry areas.

Anti-mold kit, for cleaning, priming and painting in white color, small surfaces up to 10m² attacked by moisture, mold, bacteria, biofilm, viruses... generally for use in homes, buildings and industry. Contains "FK-12 Gel" Cleaner, the primimg agent "Disperlith Primer" and the hygienic paint "Disperlith Industry".

Waterproof hygienic elastic paint, high resistance to dampness and its consequences. Treated with BioFilmStop antimicrobial technology, effective and tested against mold and yeast, bacteria and biofilm, and other pathogens such as coronavirus. Use in the food industry, health sectors, hospitals, industry, civil works and buildings in general.

Anti-humidity hygienic sanitary paint, high resistance to dampness and its consequences. Treated with BioFilmStop antimicrobial technology, effective and tested against mold and yeast, bacteria and biofilm, and other pathogens such as coronavirus. Use in the food industry, health sectors, hospitals, industry, civil works and buildings in general.

Ecological hygienic paint ECOLABEL, excellent finish and quick drying, treated with BioFilmStop antibacterial technology. Hygienic painting on walls, low and medium stress ceilings. Inside hospitals, food industry, industry in general, schools, offices, buildings, dwellings.

Hygienic waterbased enamel with high resistance to attack of mold and microorganisms, easy application and renovation, fast drying and exceptional adhesion. For painting and renovating multiple surfaces up to medium stress on walls, ceilings, panels, fixtures, objects, wood, 3D prints, plastics, primed metals, alloys, mineral surfaces...

High resistant and water-based epoxy hygienic paint that dries even at low temperatures. Treated with BioFilmStop technology against molds, bacteria and biofilm. Suitable for food industry, health sector, industry in general and where a high performance and low odor paint is required.

Hygienic paint for a quick renewal, high resistance to dampness and its consequences. Treated with BioFilmStop technology against molds, bacteria and biofilm. Suitable for food industry, health sector, industry in general and in buildings with problems of moisture and microorganism.

Hygienic paint for extreme situations, high resistance to humidity and its consequences, treated with BioFilmStop antimicrobial technology against moulds, bacteria and biofilm. Mainly used in extreme outdoor or well ventilated indoor situations. Solvent-based.

Dearomatized solvent to dissolve the hygienic paint Renolith FK-32 and for the cleaning of tools after painting.

Especially in the food industry, but also in other health-related sectors, in the paper industry, in industry in general, in buildings with construction pathologies, and in prone climatic zones, the existence of fungi and mold on interior and exterior walls and ceilings, together with other pathogenic microorganisms such as bacteria and biofilm, and viruses, is very common. Industrial proces...

If mold, fungi, bacteria, viruses and microorganisms must be solved and prevented anywhere, it is on the open surfaces of walls, ceilings, baseboards and floors, it is in hospitals, healthcare centers, clinics, operating rooms, etc. Undoubtedly, healthcare-acquired infections (nosocomial infections or HCAIs) are a serious public health problem worldwide. We all know someone who went to a hospital ...

In the food industry and healthcare sector there are walls, ceilings, baseboards, pavemenets and other unpainted mineral bases affected by humidity and its consequences. The most visible problems are salts (saltpeter) and molds, although these conditions are usually accompanied by others that are not visible, such as bacteria, biofilm, spores, crystals, etc. Some well-known examples are the minera...

In this document you will find the details of the WAGNER SF 23 Plus airless mixed equipment with air, with which you can easily apply Fakolith paints, with heated hose option, both aqueous dispersion paints and high solids paints. It is indicated the details of nozzles, guns, pressures, etc. suitable for each product and that were tested in Wagner Germany.

The results obtained in official tests carried out with viruses of the Coronavirus family, under the BSI ISO 21702:2019 standard, confirm that in just 2 hours of contact, our Hygienic and Foodgrade paints and coatings treated with Fakolith's BioFilmStop Technology reduce the viral load by up to 99.49%.

The connection of human health with animal health and the environment is a fact and the One-Health concept is positioned as a necessary global strategy, in which the collaboration of all related activities will be needed; veterinary, biology, medicine, pharmaceuticals, industry and of course, the political class. Below is an approach to these concepts and our holistic technological solutions.

In this document you will find the details of the WAGNER SF 23 Plus airless mixed airless equipment, with which you can easily apply Fakolith primers and food paints, without the option of heated hose, both aqueous dispersion paints and high solids paints. It is indicated the details of nozzles, guns, pressures, etc. suitable for each product and that were tested in Wagner Germany.

High performance heavy-duty safe coatings to eliminate, encapsulate and/or reduce exposure and contamination by endocrine disruptors safe levels, depending on their use case; direct and indirect contact with drinking water, food and beverages, industrial and general building surfaces. The presence of endocrine disruptors (EDs) such as BISPHENOL A and its derivatives in these types of coatings is common, but both EFSA and ECHA plan extensive restrictions and bans, given their potential bioaccumulative hazard to humans and the environment, depending on the use case. The ideal balance between sustainability, safety, and functional performance in each use case will mark 4 coating systems for application in direct and indirect contact with drinking water, food tanks, beverage and food processing surfaces, and high-performance surfaces in general in the health, industrial and construction sectors.

Brochure about hygiene and food safety in the food industry, detailing the general risks, and the solutions that Fakolith provides in this matter with Food Grade safe certified paints suitable for direct contact with food and beverages, as well as Certified Hygienic Paints treated with BioFilmStop technology against biofilm, bacteria, mold, moisture and its consequences ...

The present project was born as a spin-off of the successful FOODTECH & COATINGS project, whose main objective was the search for natural substances and essential oil extracts, already used in the food industry, for the preservation of aqueous coatings. Thus, in the BIOTECH COATINGS project, and in synergy with the previous one, new conservation systems will be developed for the improvement and evolution of the BioFilmStop technology incorporated in Fakolith coatings, mainly used in food industries and health sectors. The technologies evaluated and tested in this project are mainly based on the use of antimicrobial peptides, bacterial and microalgae metabolites, both free and microencapsulated, either alone or combined with our previous antimicrobial technologies. The project was successfully completed in April 2021.

The main objective of the FoodTech & Coatings project was the development of alternative preservatives and antimicrobials to traditional ones, based on food preservatives and other antimicrobial substances of natural origin, for use in paints and coatings. Those that would allow establishing a novel combined system for the preservation of the coating during its storage in the container (wet phase), while providing antimicrobial film protection, were selected and tested. The development of this project was initially focused on the development and certification of the first water-based coating suitable for food contact, with a strong added value, especially for use in sectors where antimicrobial efficacy and the absence of toxic migrations were of maximum relevance, mainly the food industry, but with possible subsequent transfer to health and household sectors. In the final selection of the preservation system and antimicrobial effectiveness, free substances were also compared with microencapsulated substances, to optimize the effectiveness and efficiency of the system. The project was successfully completed in 2016.

The "APLICONS" project was conceived to develop innovative coatings, based on innovative nanoparticles, with antimicrobial activity for the construction and industrial sectors. The development of this project was based on Green Chemistry, which uses processes and products with less environmental impact, more respectful of human health and with a strong added value. The coatings developed, thanks to the oligodynamic activity of metallic nanoparticles (NPs) and without the use of conventional organic biocides, had to have an inhibiting effect on the development of microorganisms on the surface of the coating, in addition to exerting a broad-spectrum antimicrobial power against bacteria, molds, fungi and yeasts that could come into contact with it, through cross-contamination. Project successfully completed in 2014.

Mold and moisture, together with bacteria, biofilm, viruses and other pathogens, beyond an aesthetic problem, can be a serious health risk problem in hospitals, food industry, industries and buildings in general, and also in homes. With this report you will have a preliminary vision about the importance of solving and preventing their growth in a proper way.

In this document you will find details of the airless GRACO Finish PRO II 595 air-assisted equipment, which can be used to easily apply Fakolith primers and food-grade paints, without the option of a heated hose, both aqueous dispersion paints and high solids paints. The details of nozzles, guns, pressures, etc. suitable for each product are indicated and tested by Graco at Fakolith Chemical Systems.

This specific application guide for high solids epoxy paints, such as the FK-45 and FK-100 Foodgrade range of certified sanitary food grade paints, describes the general recommendations to be taken into account before applying the paints, as well as the most common problems and solutions known in general for this type of technical paints. If you have to apply these products, read this guide beforehand and you will avoid problems.

Declaration of compliance for FK-45 OEM Solvent FG which is used for the application and cleaning tools of the foodgrade-sanitary epoxy paints range such as FK-45 Foodgrade, Fk-45 Foodgrade Hygienic and FK-45 Hygienic Forte. In this declaration is collected the European legislation authorizing its use for this purpose.

Disperlith Elastic, hygienic paint treated with BioFilmStop antimicrobial technology, is highly recommended for use on walls, ceilings and roofs in the food industry, the sanitary and pharmaceutical sectors (except for direct contact with food or medicines, where our FoodGrade range is recommended), as well as industry in general and civil engineering. To ensure that there is no doubt about its recommended use in the food industry and health protection sectors, among others, Fakolith issues a Declaration of Conformity which certifies it, and in this case the Declaration of Performance and CE marking are also added.

Disperlith Industry, hygienic paint treated with BioFilmStop antimicrobial technology, is for use on walls, ceilings and roofs in the sanitary, pharmaceutical and food industry (except for direct contact with food or medicine, where our FoodGrade range is recommended). Disperlith Industry also complies with various food and health regulations. To ensure that there is no doubt about its recommended use in the Food Industry and Healthcare sectors among others. Disperlith Industry has a Declaration of Conformity, Performance and CE marking.

Disperlith Hygienic paint with BioFilmStop Technology, is specially recommended to be applied on walls and ceilings of Health Sector, Pharma and Food Industry (except if there is a direct food contact, where are only suitable the Fakolith Foodgrade paints range) and other sensitive sectors. Disperlith Hygienic also complies with several food-health regulations. To avoiding doubts about its recommended use in food industry and health sectors, Fakolith issues a Declaration of compliance which certifies, and besides an Ecolabel certificate.

Disperlith Pox hygienic epoxy paint, treated with BioFilmStop antimicrobial technology, is for use on walls, ceilings and floors in the Sanitary, Pharmaceutical and Food Industry Sector (except for direct contact with food or medicine, where our FoodGrade range is recommended). Disperlith Pox also complies with various food and health regulations. To ensure that there is no doubt about its recommended use in the Food Industry and Healthcare sectors among others, Fakolith issues a Declaration of Conformity which certifies it, and in this case also adds the Declaration of Performance and CE marking.

Renolith FK-32 hygienic paint, treated with BioFilmStop antimicrobial technology, is for use on walls, ceilings and roofs in the sanitary, pharmaceutical and food industry sector (except for direct contact with food or medicine, where our FoodGrade range is recommended). Renolith FK-32 also complies with various food and health regulations. To ensure that there is no doubt about its recommended use in the Food Industry and Healthcare sectors among others, Fakolith issues a Declaration of Conformity which certifies it.

The water repellent treatment FAKOLITH FK-7 with BioFilmStop technology, is recommended especially as a solution for moisture conditions and surface protection in Health Sector, Pharma and Food Industry (except if there is a direct food contact, where are only suitable the Fakolith Foodgrade paints range) and other sensitive sectors. FK-7 also complies with several food-health regulations. To avoiding doubts about its recommended use in food industry and health sectors, Fakolith issues a Declaration of compliance which certifies, and besides a Declaration of performance and CE marking.

FK-45 Hygienic Forte paint with BioFilmStop Technology, is specially recommended to be applied on walls and ceilings of Health Sector, Pharma and Food Industry (except if there is a direct food contact, where are only suitable the Fakolith Foodgrade paints range) and other sensitive sectors. FK-45 Hygienic Forte also complies with several food-health regulations. To avoiding doubts about its recommended use in food industry and health sectors, Fakolith issues a Declaration of compliance which certifies, and besides a Declaration of performance and CE marking.

The water repellent and oil-retardant treatment FK-3 PLUS N with BioFilmStop technology, is recommended especially as a solution for moisture conditions and surface protection in Health Sector, Pharma and Food Industry (except if there is a direct food contact, where are only suitable the Fakolith Foodgrade paints range) and other sensitive sectors. FK-3 Plus N also complies with several food-health regulations. To avoiding doubts about its recommended use in food industry and health sectors, Fakolith issues a Declaration of compliance which certifies, and besides a Declaration of performance and CE marking.

In view of the doubt as to whether Fakolith detergent and descaler cleaners need any kind of registration for use on surfaces in the food industry, sanitary sectors, as well as in general, we have made a declaration of conformity explaining that their use is authorised, in accordance with current regulations, as a surface detergent, but not as a disinfectant. Products in this category should not be confused with disinfectants such as BioFilmStop Cleaner which do require a sanitary registration.

Official validation tests of the high resistance to cleaning and disinfection of FoodGrade BioFilmStop range, Fakolith paints. Tests conducted by TÜV SÜD in Germany according to DIN EN ISO 4628-2 standard: 2004-01. The resistance to four reference formulations models in cleaning and disinfection were tested, with excellent results. We also have more internal tests with other cleaners and disinfectants trademarks. If needed, we'll test other references in our laboratories.

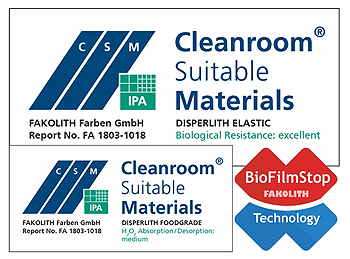

Various Fakolith food contact and hygienic coatings have been tested at the Fraunhofer Institute for recommended hygienic and safe use in cleanrooms. Here you can find various certificates regarding chemical resistance and environment-specific antimicrobial resistance of various coatings: FK-100 FoodGrade, Disperlith Elastic and Disperlith FoodGrade Elastic, and FakoPur FoodGrade. Please ask for the complete tests if needed.

Foodgrade and Hygienic paints from Fakolith are already used frequently in clean rooms for a long time.

Now the paints Disperlith FoodGrade and Disperlith Elastic, have too the tests and certifications carried out by the Fraunhofer Institute in Germany in accordance with the ISO 846 and VDI 2083 standards:

More information

In the 48th edition of the magazine “Sólo Pintura – Only Paint” was published an interview about food contact paints to our Deputy Director - Antonio Gómez. Due to space reasons it could not be published completely, but now you can read completely in our Fakolith’s blog.

'We want to be the benchmark of food contact paints in Europe'

More informationFakolith has conducted official tests with viruses of the Coronavirus family, under the BSI ISO 21702:2019 standard. The results obtained confirm that in only 2 hours of contact, our hygienic and foodgrade coatings (paints and varnishes) treated with Fakolith's BioFilmStop technology, reduce the viral load by up to 99.49%.

The Federal Association of Food Inspectors in Germany recommends the use of Fakolith FoodGrade and Hygienic paints in Europe. Specifically highlights 6 paints with Foodgrade and BioFilmStop technologies, for their contribution to hygiene and food safety.

All Fakolith paints and varnishes suitable for direct and indirect contact with food and drinks, comply with the new regulation of 2018, since 2013, both in the new limits of migration and uses of BPA, and also the compliance with the Framework Regulation EU 10/2011: "COMMISSION REGULATION (EU) 2018/213 of 12 February 2018 on the use of bisphenol A in varnishes and coatings intended to come in...

This dossier of the October-2023 issue of Tecnifood magazine addresses how climate change increases food safety risks, highlighting the importance of hygiene in the industry. Fakolith contributes with innovations such as advanced coatings and paints (FoodGrade BioFilmStop, BioHybrid ranges) to improve the food safety of surfaces involved in food production.