Published on 16-02-2018 by Fakolith Chemical Systems

In the 48th edition of the magazine “Sólo Pintura – Only Paint” was published an interview about food contact paints to our Deputy Director - Antonio Gómez. Due to space reasons it could not be published completely, but now you can read completely in our Fakolith’s blog.

'We want to be the benchmark of food contact paints in Europe'

Do you want to know who we are in 2 minutes? Watch this video

What are the food contact varnishes and paints?

It is known under this name paints and varnishes suitable for direct and indirect contact with food and beverage, food raw materials, semi-processed or finished products, drinking water, and also paints and varnishes for food packaging, such as the inner coating of cans.

What is its practical application?

Our offer is wide and growing. It includes systems for painting and/or interior renovation on food deposits, silos, cisterns, tanks, pipes... Also, for floors and pavements, walls, ceilings, sandwich panels, white-clean rooms GMP-GLP, refrigerators, machinery and facilities, trailers, components and elements used for food and raw materials transport, refrigerated trucks ... and many other solutions.

How does Fakolith ensure the food safety of these paintings?

First and as an essential requirement, we have an official Sanitary Register for producing direct contact paints. Up to now something obligatory that is not innovative, because it is only a manufacturer identification number that does not vary, like what would be the VAT of each company. However, the most important thing is that our facilities, processes and food contact paints are inspected annually by the competent health authority thereby obtaining in this way the corresponding annual inspection report. It is not just about having obtained the Sanitary Register of the company for direct contact many or few years ago, but it is about complying with the current regulations that are part of this sanitary register for direct contact.

First and as an essential requirement, we have an official Sanitary Register for producing direct contact paints. Up to now something obligatory that is not innovative, because it is only a manufacturer identification number that does not vary, like what would be the VAT of each company. However, the most important thing is that our facilities, processes and food contact paints are inspected annually by the competent health authority thereby obtaining in this way the corresponding annual inspection report. It is not just about having obtained the Sanitary Register of the company for direct contact many or few years ago, but it is about complying with the current regulations that are part of this sanitary register for direct contact.

Therefore, to comply with all requirements, since 2011 we have been making important investments in our plants in Tortosa and Germany. A part from the strict chemical industry protocols, we have added those of food safety and hygiene, a fact that sets us apart from any other paints manufacturer in the EU. Our foodgrade paints for direct contact, as regulations require, are produced only with authorized and certified raw materials. In addition, according to the regulations of Good Manufacturing Praxis EC 2023/2006 are produced in GMP-GLP areas in separated reactors from other paints, under HACCP implemented with strict safety and traceability controls, similarly to a food industry.

Each commercialized product is tested in accredited external entities, where are carried out regularly the global and specific migration tests of our foodgrade paints and varnishes, as well as organoleptic and other efficiency tests against pathogenic microorganisms, bacteria and biofilm. And in the same way CE marking tests or resistance to cleaning and disinfection assays. As food standards are more restrictive each year, and also if are formulation changes, essays with new toxic substances migration limit must be renewed regularly and / or additional included.

Fakolith complies with all applicable standards, both as a manufacturer and for products (HACCP CE852/2004, CE 1935/2004, EU 10/2011, RD 847/2011, EU 752-2017, Sanitary Registration ES-39.005259/T, CE marking,...) being audited in Spain by TÜV Rheinland Germany.

So, Should Foodgrade paints being certified?

So, Should Foodgrade paints being certified?

The foodgrade certificate is called Food Contact Declaration of Compliance. Paints and varnishes for direct contact and also indirect, such as that one’s for open surfaces like ceilings with condensation drops on food production area, among others, must necessarily have the compliance declaration of its manufacturer. It is a binding statement that apart from naming the manufacturer's data as well as registers and regulations that complies with, it must indicate the entire list of official tests carried out and for what uses paint or varnish is planned. It should also indicate for which group of foods and under what test conditions, temperature, time... can be used. It is a very serious and complex issue, because ultimately we are talking about people health, and unfortunately in the current market there are still some products that do not meet the current requirements and that put at high risk the Food Safety of industries and consequently consumers health.

Does food contact paint is generally based on epoxy paint?

It is true that this is what has been popularly known, but thanks to our research efforts we have achieved several landmarks in the EU. We were the first to harmonize with all the current standards and tested for all food groups and in wide range of colors; in 2013-14 the first epoxy-paint suitable for direct contact 'FK-45 FoodGrade'; followed in 2015-16 by the first epoxy paint free of Bisphenol A 'FK-45 FoodGrade Hygienic', and in 2016-17 the first one-component dispersion aqueous paint suitable for contact 'Disperlith FoodGrade Elastic'. Our research effort it has still not stopped and in 2018 will be incorporated at least 6 additional references to our foodgrade range, from polyurethanes to enamels and other innovative one-component formulations that will stir up certain types of application, that until now were reserved for epoxies or had no solution.

What is the added value of your paints?

What is the added value of your paints?

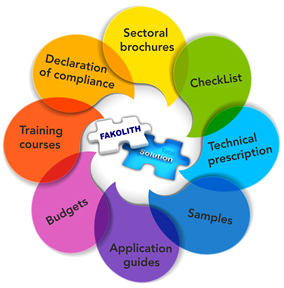

On the one hand, with our Total Solution program we provide support through our website www.pinturaalimentaria.es to the whole chain in a personalized way (official distributors, applicators, industry, engineering and architecture, health inspection ...), with technical reports, on-site samples, audit check-list, technical prescription, budget software, training courses, application guides, declaration of compliance, new products development... On the other hand, being avant-garde (Bisphenol A-free, antibacterial technology, wide range of colors…).

Do you have competitors, what kind?

Yes, of course. There are some European manufacturers with some products on the market, usually an epoxy based on Bisphenol A, and with higher limitations than our range. But, unfortunately, there are references in the market that harm everyone, and whose manufacturers do not even meet the first step, that is, they even do not have Sanitary Registry of the company, so they take advantage of this situation to be hidden from inspection, selling and even also applying with false 'food contact paints' with unknown consequences for people health. Obviously costs for these are much lower, and create unfair competition with other manufacturers, distributors and applicators who are concerned about providing food security for their customers. However, it is true that, thanks to trainings, food audits (BRC, IFS ...) and inspections, which are penetrating little by little in the industry, the client becomes more demanding, because the industrialist knows that ensuring food safety and hygiene is its legal responsibility.

What other kind of products do you develop and sell for the food industry?

What other kind of products do you develop and sell for the food industry?

Mainly, paintings of high resistance to moisture and its consequences, which have also been treated with the innovative BioFilmStop Technology (ISO 22196: 2011) against moisture and its consequences, biofilm, bacteria, mold and yeast. The BioFilmStop range has an extraordinary resistance against critical pathogens (Staphylococcus aureus, Escherichia coli, Listeria monocytogenes, Salmonella enteritidis, Pseudomonas aureuginosa, pnemophila Legionella and Aspergillus, etc ...) and contributes in an essential way to avoid contamination and toxic infections. Moreover, we have also all the necessary complements (cleaners, strippers, primers, mortars, water-repellents...) so that they can be applied in effectively and durability on different surfaces and with special environmental conditions, critical and diverse on food industry. If you visit our specific website www.foodgradepaint.com you will realize that you are faced with the only specialist in the CE sector.

What are the objectives for the future?

What are the objectives for the future?

To provide our customers and industry the access under advantageous conditions to our first milestone 'FK-45 FoodGrade', so that no one renounces at the access to a certified and quality product. Growing up in the Spanish, European and global market, for which, apart from European regulations, we are focusing on complying with and standardizing the American FDA regulations. We want to lead technology and innovation, definitely become a reference of the sector in this specialty, and achieve the recognition of our customers, providing value, safety and food hygiene, and contributing to the business growth of the food sector and the distribution sector and application of functional paints.

LINK A PRENSA