Published on 22-03-2021 by Fakolith Chemical Systems

One of FAKOLITH's major specialties are coatings, varnishes, and paints suitable for direct, indirect, or occasional contact with food, beverages, and drinking water. As an SME intensive in Research and after 10 years of continuous official research projects in the field of coatings for food contact and antimicrobial activity, we can affirm that this is an extremely complex and exciting specialty, and in any case of great importance for the health of consumers.

Given its complexity and relevance, for the food industry, as for the food packaging manufacturer, for the consumer, even for internal and external control, we will try to explain its operation in the simplest possible way, from our specialty in coatings, and through the main document 'The Declaration of Conformity or Compliance Declaration'.

Do you want to know who we are in 2 minutes? Watch this video

INDEX

1.- Extensive regulations, each year more changing and restrictive.

2.- What is the Declaration of Conformity or Compliance?

3.- Global and specific migration tests, and organoleptic.

4.- Fakolith is committed to transparency and excellence.

5.- Official Research in food contact and antimicrobial protection.

6.- And apart from this, does Fakolith perform any other tests?

7.- A wide range of solutions.

8.- FAKOLITH added value, contact us.

1.- Extensive regulations, increasingly changing and restrictive.

All materials suitable for direct contact with food and beverages are regulated in Europe by the EC Framework Regulation EC 1935/2004. This regulation then defined the materials that could be suitable to be in contact with food; plastic materials, active and intelligent materials, ceramics, adhesives, cork, metals and alloys, glass, paper.... and then develop specific regulations for each of these materials.

Regulation EU 10/2011 on plastic materials is one of the few on which Europe has developed an extensive specific regulation and which is already taken as the reference for the rest. It currently covers various plastic materials, packaging, its components and complements, varnishes, paints, coatings, utensils, parts of machines and equipment, etc...

EU 10/2011 Regulation, like all of them, undergoes periodic amendments, which usually tighten the testing conditions for these materials. For example, a relevant amendment for the field of coatings was Regulation EU 2018/213, which among other changes specified that EU 10/2011 applies unequivocally to coatings, varnishes and paints for food contact, and also limited the use and reduced the maximum permissible specific migration limit of Bisphenol A. The last modification to date, is the 15th amendment, specifically the EU Regulation 2020/1245 that although it applies a transition period of 2 years, brings new metals, NIAS (Non-intentionally added substances) and other substances to control, new and stricter migration limits, and changes in the methodology in the specific migration of repeated use, among many other changes that make it undoubtedly the European regulation of food contact stricter and more difficult to comply with, internationally.

EU 10/2011 Regulation, like all of them, undergoes periodic amendments, which usually tighten the testing conditions for these materials. For example, a relevant amendment for the field of coatings was Regulation EU 2018/213, which among other changes specified that EU 10/2011 applies unequivocally to coatings, varnishes and paints for food contact, and also limited the use and reduced the maximum permissible specific migration limit of Bisphenol A. The last modification to date, is the 15th amendment, specifically the EU Regulation 2020/1245 that although it applies a transition period of 2 years, brings new metals, NIAS (Non-intentionally added substances) and other substances to control, new and stricter migration limits, and changes in the methodology in the specific migration of repeated use, among many other changes that make it undoubtedly the European regulation of food contact stricter and more difficult to comply with, internationally.

2.- What is the Declaration of Conformity or Compliance for food contact materials?

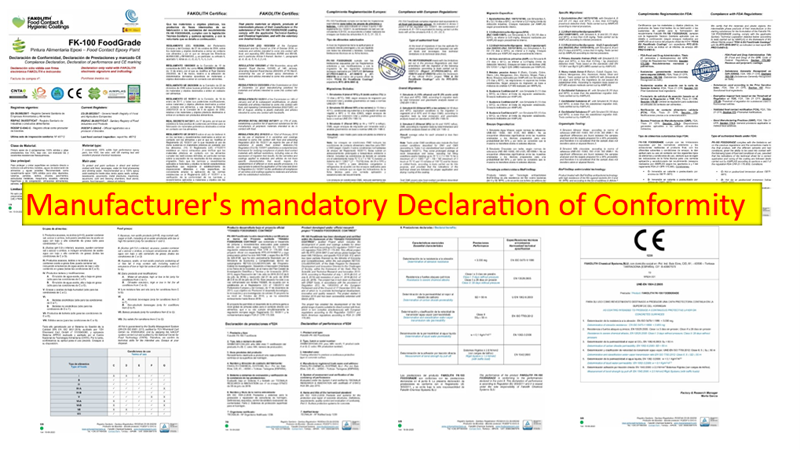

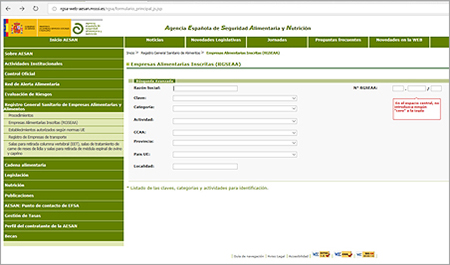

The Declaration of Conformity, or Compliance Declaration is a mandatory document for the manufacturer of materials in direct contact with food, which will help to dissect the producer and the product, providing the industrialist, those responsible for food safety and inspection, the necessary data to determine that the material is safe for the use to be given. Let us say that 'The Declaration of Conformity' is like an X-ray of the manufacturer of this type of materials and of each product.

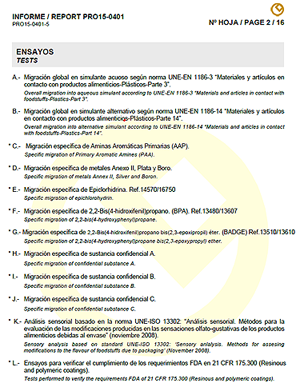

The Compliance Declaration must contain all the manufacturer's data, including its RGSEAA Sanitary Registration (in Spain 'code 39' for direct food contact materials). Also, a list of all the Regulations that the registered manufacturer complies with, as well as a description of the product and its basic conditions of use. In addition, it must cite the required tests performed in approved laboratories, global migrations, generic specific migrations, specific migrations according to formulation, organoleptic tests, as well as other additional tests pertaining to the type of product at the functional level.

The responsibility for making the declaration of conformity lies with the manufacturer of paints, varnishes, and coatings for food contact, who, as the developer, is the only one who knows the components of its product. It would be absurd to try to transfer the responsibility of making it to the application company, or to the user industry of our coatings, either in its production process, facilities or as part of its packaging or product.

Given our experience, we can affirm that it is necessary to have a comprehensive scheme of NDAs (Non-Disclosure Agreements) signed with suppliers of food raw materials, as well as with external accredited certification and testing centers.

From the Declaration of Conformity, depending on its transparency and content, industrial users, packaging manufacturers and food processors, as well as auditors of food quality standards (ISO, BRC, IFS ...) and health inspection, can more easily verify that they are dealing with a supplier and product that complies with food safety:

A technical data sheet for a food contact coating, paint or varnish is necessary for its proper use and application at a functional level, but it is not the document required by the Regulation in relation to food safety. It is the Declaration of Compliance that must demonstrate its validity as a safe product and producer, and it must be available at all stages of marketing of the product (except to the final consumer).

The tests cited in the declaration of conformity, and performed on each product placed on the market, must be available to any customer upon request and for inspection.

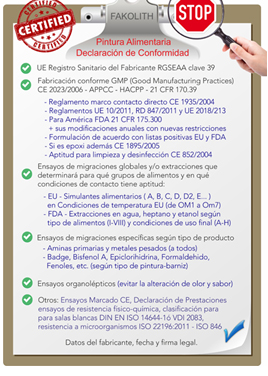

A piece of advice to the industrialist, which we apply in a similar way in Fakolith when evaluating the raw materials we use, would be to include in the HACCP, 'before acquiring a material suitable for direct contact with food, ask for the manufacturer's Declaration of Conformity as a first step'.

We remind you that it is the responsibility of the food industry to verify that the materials used are suitable and safe. In addition, the latest versions of IFS and BRC already indicate the necessary vigilance and verification towards suppliers of this type of materials in direct contact with food.

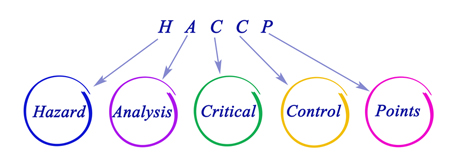

The website of the Spanish Agency for Food Safety and Nutrition (AESAN), has a search engine for registered companies, which by typing the manufacturer's company name will indicate its Registration and Key, or the absence of this.

For example, if you type FAKOLITH, you will see that the result is: Fakolith Chemical Systems, SLU with Registration 39.005259/T. 'Key 39: Materials and articles intended to come into contact with foodstuffs'.

By the way, it is worth remembering that in FAKOLITH, although we have a Sanitary Registration for materials in direct contact, it is not a guarantee by itself, since it is an identification number of the manufacturer, which once obtained, like the VAT number, does not change. What does vary constantly are the regulations linked to it as appropriate, and it will be the responsibility of the manufacturer of materials in direct contact with food to be up to date with them, applying the necessary procedures and tests as appropriate to each product marketed.

By the way, it is worth remembering that in FAKOLITH, although we have a Sanitary Registration for materials in direct contact, it is not a guarantee by itself, since it is an identification number of the manufacturer, which once obtained, like the VAT number, does not change. What does vary constantly are the regulations linked to it as appropriate, and it will be the responsibility of the manufacturer of materials in direct contact with food to be up to date with them, applying the necessary procedures and tests as appropriate to each product marketed.

We are talking about Food Safety and not about whether a product is cheaper, more expensive, better or worse. However, a manufacturer with Sanitary Registration (in Spain), is traceable and is under the surveillance of the Health Authority Inspection, national and international. This is important, for example, in case of health alarm due to food contamination, thanks to the protocols established for the manufacture according to CE 2023/2006 and the required traceability of all processes, it will be possible to create and communicate a Food & Feed Safety Alert (RASFF), withdraw batches, investigate the causes and establish the responsibilities that correspond to the manufacturer of the material, to any of its suppliers of raw materials, to the choice of the product, or its application, misuse, etc...

On the other hand, if the same thing happens with a manufacturer that does not have the proper Sanitary Registration, Declaration of Compliance, etc., it is likely that it does not have all the necessary measures to ensure food safety and its associated procedures, and it is also likely that it has never been inspected in this area, since not being registered, it may remain hidden from the vigilance of the Authorities.

3.- Why are trials of global and specific migrations necessary?

Materials authorized to be in direct contact with food may migrate, i.e. transfer chemical substances to food, depending on the type of material, contact time, temperature, and type of food with which they are in contact.

In the EFSA (European Food Safety Authority) video, you will find a basic definition of materials suitable for direct food contact.

The migration tests in Europe, as well as the extractions tests in the US, are used to determine that the authorized substances that could migrate into food are within the maximum permitted limits, so that they do not represent a health risk.

Testing the migration of every packaging or coating in contact with every food on the market would be a virtually impossible task, so the European Regulation EU 10/2011 has assigned chemical simulants that encompass several food groups, broadly speaking:

It is important to always consult the latest consolidated version of Regulation EU 10/2011, which is the one that includes all amendments to date, as well as the necessary details, tables, exceptions, correction factors and alternatives for various cases.

Thus, coatings and packaging in Europe must be tested in immersion/contact with these chemical simulants to determine the overall migration capacity of substances to each simulant, the maximum migration limit allowed being 10 mg/dm² of contact surface or 60 ppm (60 mg/kg food).

In addition, there are different migration test conditions, currently from OM0 to OM9, in practical terms, from cold temperatures and short contact time to prolonged contact and temperatures up to 175ºC. The higher the temperature, the greater the possible migration of substances into the food.

In addition, there are different migration test conditions, currently from OM0 to OM9, in practical terms, from cold temperatures and short contact time to prolonged contact and temperatures up to 175ºC. The higher the temperature, the greater the possible migration of substances into the food.

The test conditions will determine the safe use conditions for which the coating/packaging is suitable for direct food contact, both in terms of contact time and maximum temperature. For example, a take-away coffee cup is not the same as an industrial level tank where a food or beverage is stored in a food transformation process.

From this we can understand that, if we leave a plastic water bottle in the sun in the car, the water will taste bad, since this bottle is probably designed for use in a certain range of temperatures and exposure, which is not contemplated in this case. There are plastics designed to withstand high temperatures, for example, those that indicate their suitability for use in the microwave, while others are not. If we exceed the limits of use, it is possible that undesired migrations may occur that can significantly alter the organoleptic, food safety and functionality. As a curious fact, for example, the migration and extraction tests for our FK-100 FoodGrade paint take up no less than 20 pages, because if multiple uses need to be tested, many migration tests will be required.

But this is not the end of the story, if they are coatings for surfaces or packaging of single-use, which are what the consumer usually uses when buying food, for example, a bottle of milk or a fruit and vegetable packaging, the coating must comply with all the maximum limits at the first migration, which is where the greatest risk is concentrated. For repeated use packaging and surfaces, more at the industrial level, or reusable packaging, the third migration is taken as a reference.

Once the necessary tests have been carried out with the chosen simulants, and they comply with the maximum permissible overall migration limits, we must move on to testing the specific migrations. Each coating or packaging, depending on its formulation/composition, must comply with the maximum specific migration limit (SML) of certain substances.

For example, all coatings and packaging must always comply with the maximum limits for specific migration of aromatic amines and heavy metals, among others, but also with those specific to their formulation; for example, in the case of products based on epoxy resins, they must comply with the maximum limit of specific migration of Bisphenol A of the latest EU Regulation 2018/213, which reduced 10 times the allowed SML of BPA, but they must also comply with the specific Regulation for this epoxy group, EC 1895/2005, which contemplates another series of specific migrations such as BADGE, NOGE, BFDGD, etc...

It should be noted that only some calculations of specific migrations can be performed theoretically, i.e. without testing, by mathematical model and according to the indications of EU 10/2011 regulation, with a scientifically based overestimation. On a practical level, for example, it will be possible in cases where we know perfectly well the composition of each substance contained in each raw material, which, being on the positive list, has an SML, and it is the case that this content is lower than the maximum permitted migration limit.

As mentioned above, this implies having confidentiality agreements between raw material suppliers, and generally with an accredited external laboratory, which ensures that these theoretical calculations are verified.

Once the above is fulfilled, organoleptic tests must be carried out to verify that, in spite of being compliant in relation to food safety, there are no significant alterations in odor and taste, in accordance with the intended use. The UNE-ISO 13302:2008 standard is used as a reference to evaluate olfactory and taste modifications.

4.- Fakolith is committed to transparency and excellence

In our case, from www.foodgradepaint.com of Fakolith, we have opted for transparency and we have published the Declarations of Conformity of our varnishes, paints and coatings for direct, occasional or indirect contact with food and beverages, link here.

Our Compliance Declarations are regularly updated to include new tests required by changes in regulations.

In food safety, sufficient is insufficient, only excellent is possible

It is true, in Fakolith we have taken this matter very seriously, although in the rules and regulations, there is room for certain interpretations. In our case, for the sake of food safety we have decided to always work with the most demanding interpretation of the regulations, as well as to constantly investigate with official Research projects in this field to improve food safety, sustainability, and functionality.

5.- Pioneers in official research in food contact and antimicrobial protection

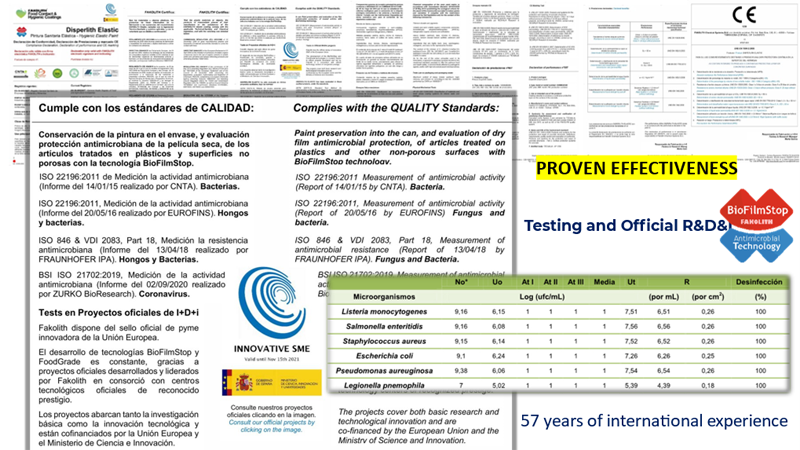

Since 2009 Fakolith has participated in more than 8 official research projects, in consortiums with universities, technology centers and other companies, and in the last 4 years it has also been the designer and leader of these projects, which is why it is considered by the Ministry of Science and Innovation as a European R&D&I Intensive SME.

A clear example is that thanks to the Official R&D&I FDA & EU FoodGrade Coatings Project, FAKOLITH has been the first global manufacturer to certify varnishes and paints suitable for food contact, with antimicrobial technology, which simultaneously comply with the 2 international food contact reference regulations, the American FDA 21 CFR 175.300 and also the European EU 10/2011.

The development of paints and varnishes with double FDA and EU certification has represented a great innovative effort for our R&D department. Both regulations differ in their conception, evaluation of raw materials and testing criteria, while the European one is based more on migrations, the American one is based on extractions. Complying with both simultaneously in the same product provides our customers with the best possible guarantee in terms of food safety and hygiene.

FAKOLITH and the constant improvement of sustainability

Fakolith is already looking to this future with the official R&D&I project 'BioHybrid Food Contact Coatings' in which the first range of bio-based hybrid coatings suitable for direct contact with food and beverages is being developed and certified in accordance with European and North American regulations.

It is necessary to know that biodegradable is not always synonymous with safe for food contact, as it can compromise functionality and increase permitted migrations, or even generate problems for celiacs in some cases.

Therefore, Fakolith in this project is investigating all options to develop and certify bio-based hybrid coatings with an ideal balance between sustainability, recycling, and functionality, all without compromising food safety, which we must never lose sight of.

Here you can find information about our R&D&I projects.

6.- And apart from this, does Fakolith perform any other tests?

In our case, paints, varnishes, and coatings for direct contact with food, beverages and drinking water, from FAKOLITH we also understand as fundamental additional tests that determine the functionality of the product, that is to say that apart from not representing a health risk in direct contact with food and beverages, they fulfill their function as a coating. The most common tests that we perform, both in external organizations and in our R+D+i projects are:

In general:

To simplify the location of these tests, FAKOLITH includes them in the Declaration of Conformity, Performance and CE marking.

Here you can find information about our Compliance Declarations

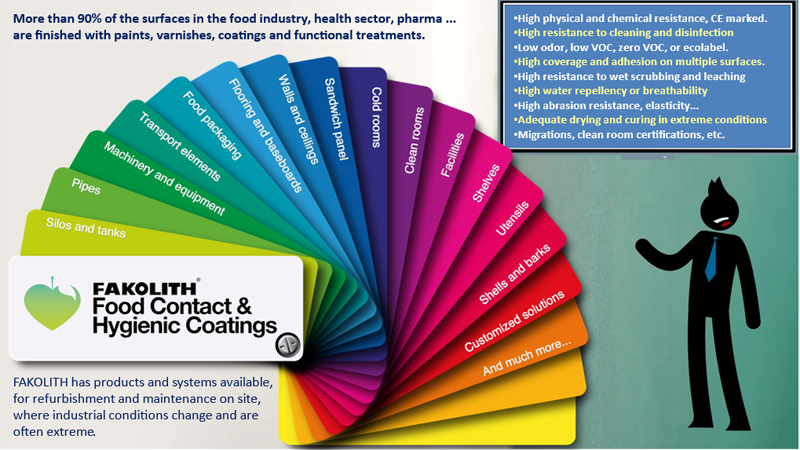

7.- A wide range of food and sanitary solutions

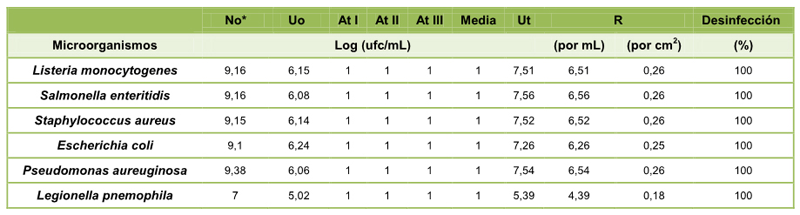

While the primary function of FAKOLITH's FoodGrade paints, varnishes and coatings is to prevent the migration of toxic substances into food and their manufacturing environments, this range is not only used for direct contact, but also due to its performance and proven antimicrobial effectiveness against pathogenic microorganisms, it is used on multiple surfaces in the food, healthcare, pharmaceutical and general industry sectors.

While the primary function of FAKOLITH's FoodGrade paints, varnishes and coatings is to prevent the migration of toxic substances into food and their manufacturing environments, this range is not only used for direct contact, but also due to its performance and proven antimicrobial effectiveness against pathogenic microorganisms, it is used on multiple surfaces in the food, healthcare, pharmaceutical and general industry sectors.

Using Fakolith's FoodGrade and BioFilmStop range of coatings in the food, healthcare and pharmaceutical sectors contributes positively to compliance with hygiene and food safety and sanitary standards in general.

A clear example of indirect food contact are ceilings, walls, floors and other surfaces in food processing industries, where condensation droplets can carry chemical and biological contaminants into the food, which can cause cross-contamination.

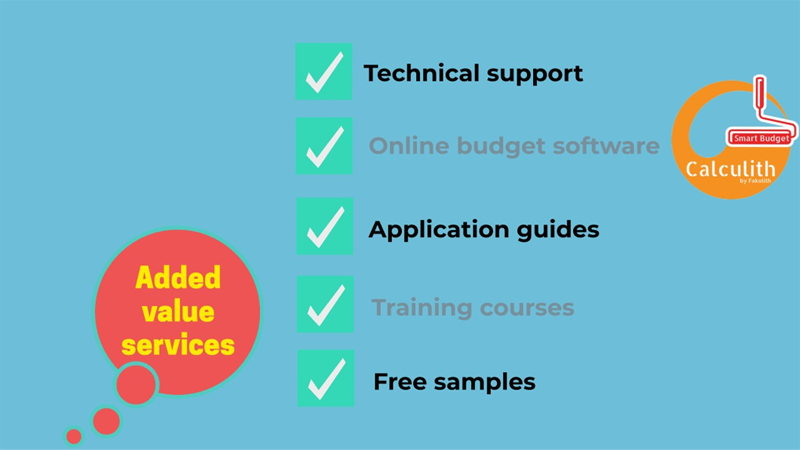

8.- FAKOLITH's added value, contact us.

9.- Links of interest:

Download this post in PDF format

Certified food grade and sanitary paints

Contact us